KEVIN MONKS

RESTORATION

PAGE

2

Car

stripped down to bear bones!

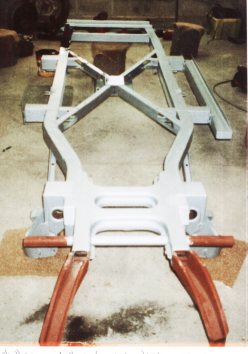

PIC 1

Chassis as returned from shotblasting, repairs already commenced to x bracing

(center bracing).

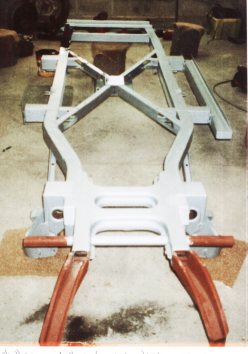

PIC 2

Rear cross braces of chassis shown

PIC 3

Corrosion presents after braces removed (holes clearly visible).

PIC 4

Picture showing new metal let in and replacement cross braces I had made up.

PIC 5

Replacement spring hangers I made compared to corroded originals (I made the

new ones 6mm wider then inserted 2x3mm washers) this was to allow adjustment of

the leaf springs from side to side by shimming should I have got the

measurements wrong. As it was I hadn't.

PIC 6

Photo of the repaired chassis (upside down) with primer applied.

I had the chassis shot blasted to basically give

me a clean base to work from and also identify any corrosion.

On it's return numerous areas of corrosion had

come to light. Now rightly or wrongly I decided to basically plate over the

affected areas with 3mm plate. Each surface was first treated to weld through

primer, I then seam welded in plate on both sides of the chassis so I

ended up with mirror image repairs.

I approached the repair in this manner for two

reasons;

1) By doing the repairs exactly the same to both

sides of the chassis means even weight distribution.

2) Due to the repairs being seam welded and

leaving the original metal in place the chassis should be more rigid, and

therefore be more taut on the road.

The downside is I've added additional weight to

the car and the possibility of corrosion occurring between the

metal let in, and the original chassis. With regards to the additional

weight I don't think this will affect the day to day driving of the car to

such an extent it will take away any pleasure. As to the corrosion the

weld through primer should eliminate any problems along with injecting the

chassis with waxoyl.

I made up new spring hangers and welded them into

place.

As the Daimler will be driven by both myself

and my wife, Anne, I decided to incorporate other modifications to the

chassis. These include conversion to rack and pinion steering and telescopic

rear dampers.

I purchased a damper kit which includes a

frame which is bolted down onto the chassis near the spring bump

stops. The instructions suggest drilling and tapping the chassis to mount the

frame, which in turn supports the top of the shock absorbers. As the chassis

is only about 2mm in thickness I thought it would be a bad idea to tap a

thread into such a small surface area. I decided on a belt and braces

approach by first drilling the chassis, then welding in nuts to accept

the frame securing bolts. I then plated over the captive nuts to prevent them

from being pulled through.

The next stage was to fit new chassis sills ( my car is a 'B' spec), these

were purchased from David Manners. As the sills were only constructed

from spot welds I again seam welded these items and capped of the front of

them. This is to prevent debris thrown up from the front wheels entering the

sill sections.

The chassis was then treated with paint obtained from a ship yard.

This consists of a primer (silver in colour), an undercoat (matt black) and a

top coat (gloss black). The first two were hand brushed on with the top coat

being sprayed. My logic for using this paint was that it is designed for use

in salt water, and so should be okay for road use. The finished chassis

will be eventually sprayed in a waxoyl type product which should take the

sting out of road chips.

I have since managed to trace a sizable amount of history relating to the

car. If anyone wants advice on how to do this I'll only be too happy to advise

them. I'd also appreciate any feedback on how you think I'm tackling the

restoration whether it be positive or negative.